With our experience in the medical and life sciences industries, we understand the importance of creating reliable, cost-effective mechanical components for high-tech robotic systems. We work closely with engineers to ensure components are optimized for manufacturability and functionality, whether they are sensor housings, structural elements, or lightweight parts.

In Robotics Components

In robotics, balancing strength and weight is crucial to performance. Parts that are too heavy increase power consumption and limit mobility, while components that are too weak can fail under stress. We help engineers solve these challenges by offering the following:

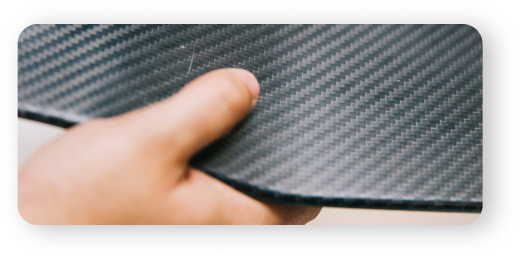

Material Expertise

We help you select the suitable materials for your project. With experience in various metals, carbon fiber, and high-performance plastics, we ensure durability without adding unnecessary mass. This is especially important in extending battery life and improving the agility of robotic systems.

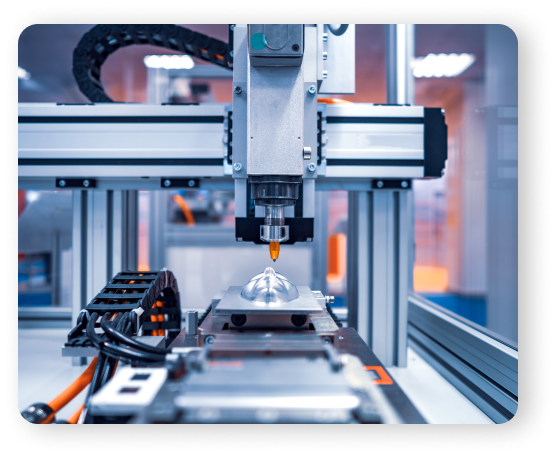

Structural Optimization

Using advanced tools like finite element analysis (FEA), we optimize designs to reduce material usage while maintaining structural integrity, helping robots withstand repetitive tasks, high-speed movements, and demanding environments.

Precise sensor integration is critical to performance. We apply our expertise from the medical device industry to ensure that sensor housings and mechanical parts are designed with precision in mind, meeting the exact requirements for sensor placement and performance:

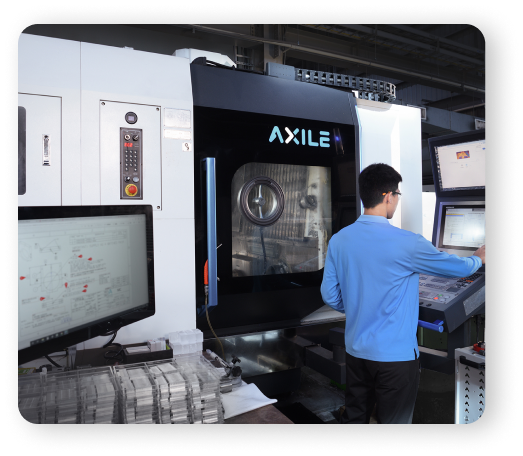

High-Precision Machining

We use advanced CNC machining to create components with tight tolerances, ensuring accurate sensor alignment and placement. Our capabilities ensure that sensors perform reliably, even in challenging conditions.

System Integration

Our designs account for vibration, thermal expansion, and mechanical stress, ensuring sensor accuracy over time and in varied operating environments.

Robotics companies often require flexible manufacturing for prototyping and early-stage production. ACHB specializes in high-mix, low-volume production, offering the ability to quickly adapt to design changes without the constraints of mass production:

Flexible Manufacturing

We can accommodate frequent design iterations and produce low volumes efficiently, supporting robotics engineers in refining their designs and validating new concepts.

Multiple Manufacturing Techniques

From plastic injection molding to forging and casting, we provide a wide range of manufacturing processes to meet the specific needs of your robotics project, enabling smooth transitions from prototyping to full-scale production.

Optimized Robotics Design for Performance and Cost Efficiency

From the process of cost-effective production to overcoming complex mechanical demands, robotics systems face various challenges. At ACHB, we make the most of DFM principles in optimizing your design while addressing mechanical hurdles such as intricate movements and environmental stresses. Our innovative solutions ensure exceptional performance for your robotics components without exceeding the budget constraints.

We help simplify complex geometries, reduce the number of components, and select cost-effective materials to minimize production costs while ensuring performance and quality.

As your production volumes grow, ACHB will scale with you. Our CNC machining, plastic injection molding, and forging capabilities ensure we can handle your production needs, maintaining precision and quality at every stage.

We design parts that withstand high stress and repetitive movements, using wear-resistant materials and predictive simulations to ensure long-lasting performance.

Robots often operate in environments with temperature fluctuations and vibrations. ACHB applies its experience in these areas to design components that manage these stresses effectively, ensuring reliable performance.

Experts In Component Design

By partnering with ACHB for your component design needs, you can ensure your designs are optimized for manufacturability, cost efficiency, and scalability, setting the stage for successful production and long-term performance. Contact our team to learn more about how we can support your next project.